Austrotherm

Simplicity as a key success factor

Austrotherm creates efficiency and transparency through clear processes and simple structures – whether in product development, production or customer service. Complexity is deliberately reduced to promote rapid decision-making and practical solutions. On the following pages, solutions are presented that successfully contribute to the simplification of processes and content.

Internal communication simplified by digital tools

Clear and regular information sharing and open communication help everyone to pull together and foster a shared sense of responsibility. In addition, good internal communication helps to avoid misunderstandings, respond more quickly to challenges and share innovative ideas, ultimately leading to greater cohesion and higher productivity. In Austria, digital screens have been used since 2023 to keep all employees informed about current developments. A further international roll-out is planned and has also been successfully implemented in Wittenberge, Germany, since 2024. The employee portal, which has been in use throughout Austria since 2024, serves as an accessible, extended communication channel with important information and news about the company and its departments, links, events, etc., as well as for ongoing exchange with employees.

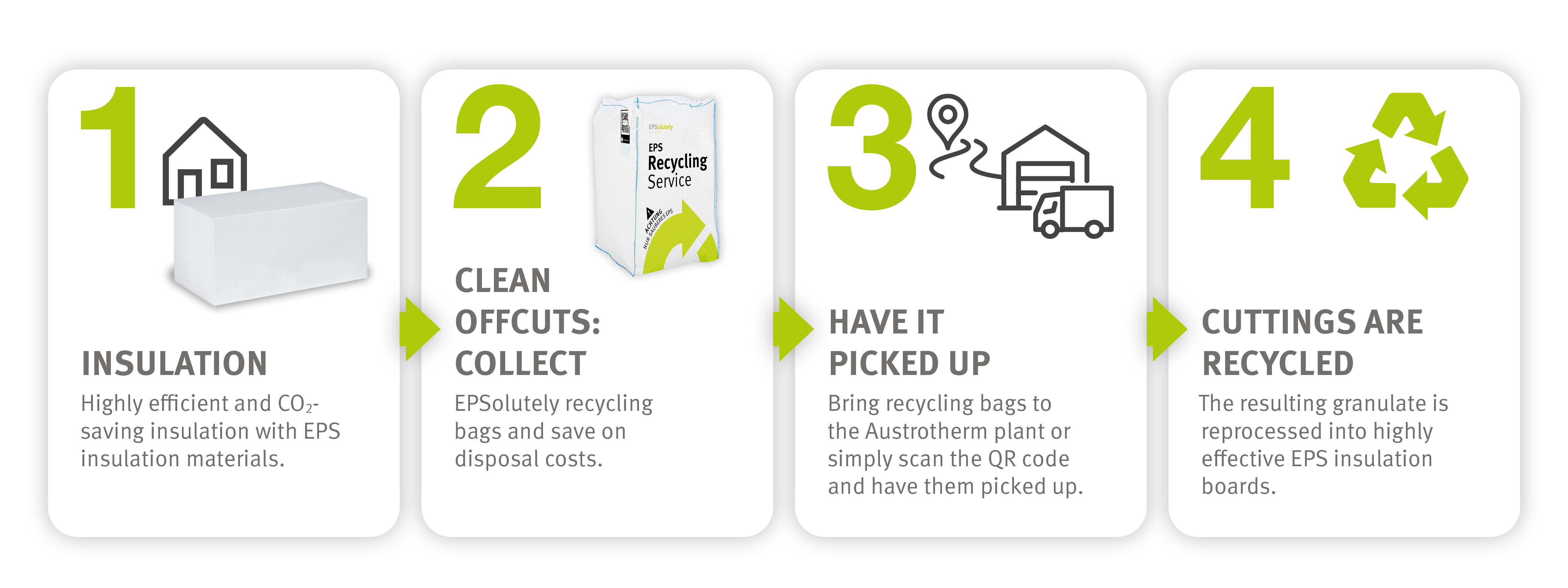

Simplify the use of sustainable solutions

Austrotherm is working hard to remove the obstacles that prevent customers from not only wanting to act sustainably, but also from being able to do so. An important step in this direction is the company‘s participation in the innovative EPSolutely research project, which is led by Fraunhofer Austria, funded by the Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology and managed by the Austrian Research Promotion Agency (FFG). The motto is circular economy instead of downcycling. Together with all players along the value chain, the aim is to establish an economically and ecologically sensible circular economy for EPS. Since September, Austrotherm and other project partners have been offering the EPS pick-up service throughout Austria. With the free collection and return of EPS cuttings, a new milestone has been reached. After collection, the material is processed and reintroduced into production in the factory. The clear customer benefit: free collection from the construction site or company saves hard cash for disposal. For optimal information transfer, EPSolutely developed an easy-to-use web application.

Simply use the sun

Access to alternative energy must be easy. With the Sonnenarena Wittenberge in Germany, as well as photovoltaic systems at the Austrian plant in Purbach and in Dynin, Czech Republic, Austrotherm is setting a clear example. The Sonnenarena in Wittenberge covers an industrial area the size of six football pitches and will generate a significant portion of the electricity required. A 340 kWp photovoltaic power plant on the roof of the production and storage facilities in Dynin, Czech Republic, also covers up to 80% of the electricity consumption. The use of solar energy is being expanded in Austria. As part of this, a photovoltaic system with an output of almost 220 kWp was installed on the factory premises in Purbach, Burgenland, this year. This will enable Austrotherm to double the amount of solar power generated in Purbach.

“The 2,700 kWp of rated power that we can generate with the solar arena is roughly equivalent to the electricity consumption of 1,000 households.”

Lars Peters,

technical director Austrotherm Germany

Keep it short means short distances

Well-planned locations help to reduce complexity. With four new locations in four countries – Austria, Croatia, Greece and Turkey – shorter transport routes, lower energy consumption and optimized processes practically “arise by themselves”. Being closer to customers and raw material sources makes logistics easier and more environmentally friendly. This is how sustainability is implemented pragmatically and without unnecessary expense – saving time and costs and simplifying processes.

A good example of this is the Greek EPS producer Monosi, which will continue to be firmly anchored in the Greek market and will remain a well-known brand of insulation material. Continuity and trust are ensured by taking on all of the employees. As a family-run company with a long tradition, Monosi is a perfect fit for Austrotherm. The expansion of the product range to include XPS will give Austrotherm a greater presence in the market.

The further expansion of existing plants in Samac and Dynin has also made it possible to optimize storage capacities at existing plants – in Dynin, the conversion of the warehouse has even doubled storage capacity. Thanks to this reorganization, the company can now respond more efficiently to customer requirements and offer a better service. The completion of the new, state-of-the-art warehouse in Samac is planned for Q1 2025.

In Arad, the office buildings were renovated and employees now work in a modern, efficient environment with state-of-the-art equipment.

“Monosi is the ideal addition to our production network in Europe. With the first location in Greece – centrally located near Athens – we can further expand the delivery and service quality for our customers.”

Dr. Heimo Pascher,

CEO Austrotherm Group

Clear rules and applications for a safe working day

Simple, easy-to-understand safety standards and processes directly minimize risks without hindering the workflow. Regular training and easily accessible safety measures ensure that all employees can quickly understand and apply the guidelines. At Austrotherm, “Make it simple again!” is lived. The “Golden Rules” and “Incident Reporting App” are already fulfilling their purpose. The “Golden Rules” have been rolled out in all countries. Rules of conduct formulated in a simple and understandable way define what needs to be observed to ensure maximum safety in the workplace. A poster in central locations such as the canteen or by the staircase in the branches contains everything on a single page. Less is more.

In Germany and Austria, the specially developed web application for reporting incidents is already in use. It can be conveniently accessed by scanning a QR code. Anyone who notices an unsafe situation or action in their work environment enters the necessary information and uploads a photo or video. Whether it‘s dangerous storage or a blocked fire door, saving the information triggers an email to the responsible safety specialist, who decides on a course of action. The evaluation can be shared with other branches.

Intuitive access to the product world

Clear explanations and simple navigation help customers to find product information faster and more quickly and understand its advantages. This reduces queries, strengthens trust and makes the search for information more efficient – ideal for clear communication and high customer satisfaction. With Austrotherm‘s new digital “product finder”, all products and their applications can be viewed at a glance with a single click. The processing videos provide practical assistance with the application.

Standardized inspection processes in production

In quality assurance, the approach helps to standardize testing processes and focus on the essentials. Important control points are clearly defined, digitized and easily structured thanks to various interfaces, which improves traceability and error detection. This helps to maintain high quality without unnecessary checks or complicated procedures slowing down the process. A good example of this is the EPS Density Report, which is already in use in Austria and Slovakia, planned for Poland and in the test phase in Croatia. Its task: to optimize the use of raw materials. To do this, machine data – including weight – is read directly from the blockmolds. If a block is produced that is too heavy, this results in higher material costs. This individual information is summarized in a report and displayed in real time, eliminating the need for manual checking.

New faces at Austrotherm

Since January 2024, Stephanie Poller, as Head of Marketing & Communication, has been applying the skills she has gained in an international environment to the benefit of the entire Austrotherm Group, working with her team to take the next strategic marketing steps. In October 2024, the EPS producer Monosi and all its employees were taken over 100 percent by the Austrotherm Group. Ilias Strousidis has since successfully continued to run the family company as CEO of Austrotherm Greece, thus ensuring continuity and confidence in the quality and service of the company. Since November 2023, Stephan Broucek has been head of purchasing at Austrotherm Austria, taking care of purchasing and fleet management to achieve efficient solutions and the best possible prices for the local market.